In the era of modern industry, increasing efficiency and productivity is crucial. One tool that plays a significant role in achieving these goals is the digital logsheets. The transformation from manual logsheets to digital logsheets allows companies to more effectively track production activities, manage data, and enhance their competitiveness. In this article, we will discuss how digital logsheets contribute to the development of production processes and help companies improve their competitiveness in the global market.

Benefits of Digital Logsheets in Production Processes

Read More: Real-Time Quality Monitoring: The Role of Digital Logsheets in Production Control

1. Data Collection Efficiency

Digital logsheets enable real-time data collection of production activities. Utilizing this technology reduces the time spent on manual data entry, which is often prone to errors. With digital logsheets, data can be automatically entered through sensors or software connected to production machines.

2. Reduction of Human Errors

Manual logsheets are often susceptible to human errors, such as mistakes in recording numbers or incomplete information. Digital logsheets minimize these risks by ensuring that recorded data is more accurate. This helps companies make better decisions based on valid data.

3. Improved Data Accessibility

With digital logsheets, the entire team can access data easily, anytime and anywhere. This accessibility allows for more comprehensive and real-time monitoring of production processes. Managers can view production performance directly from their devices without needing to be on-site.

4. In-Depth Data Analysis

Digital logsheets also offer opportunities for more in-depth data analysis. By collecting and storing large volumes of data, companies can analyze production trends, identify patterns, and make predictions for future planning. This can aid in faster and more precise decision-making.

Enhancing Competitiveness through Digital Logsheets

Read More: Advancing Towards Industry 4.0: Transformation with Digital Logsheets in Production

1. Optimization of Production Processes

With accurate, real-time data, companies can identify areas needing improvement in their production processes. This enables companies to reduce machine downtime, increase efficiency, and maximize resource usage. Ultimately, this contributes to higher output and product quality.

2. Enhanced Market Response

In a competitive industrial world, the ability to respond quickly to market changes is key to success. Digital logsheets provide companies with the flexibility to adjust their production processes based on market demand. Real-time data allows companies to modify production strategies without delay.

3. Reduction of Operational Costs

By adopting digital logsheets, companies can reduce operational costs. The need for paper and manual data entry decreases significantly, directly saving costs. Additionally, with more efficient processes and fewer errors, companies can also lower costs related to repairs or production adjustments.

4. Compliance with Industry Standards

In many industries, compliance with safety and quality standards is crucial. Digital logsheets allow companies to better adhere to these standards. All data related to production processes, product quality, and machine maintenance can be stored digitally and easily accessed during audits or inspections.

Implementation of Digital Logsheets Across Various Industries

Read More: Increasing Production Transparency with Digital Logsheets: The Case of the Food Industry

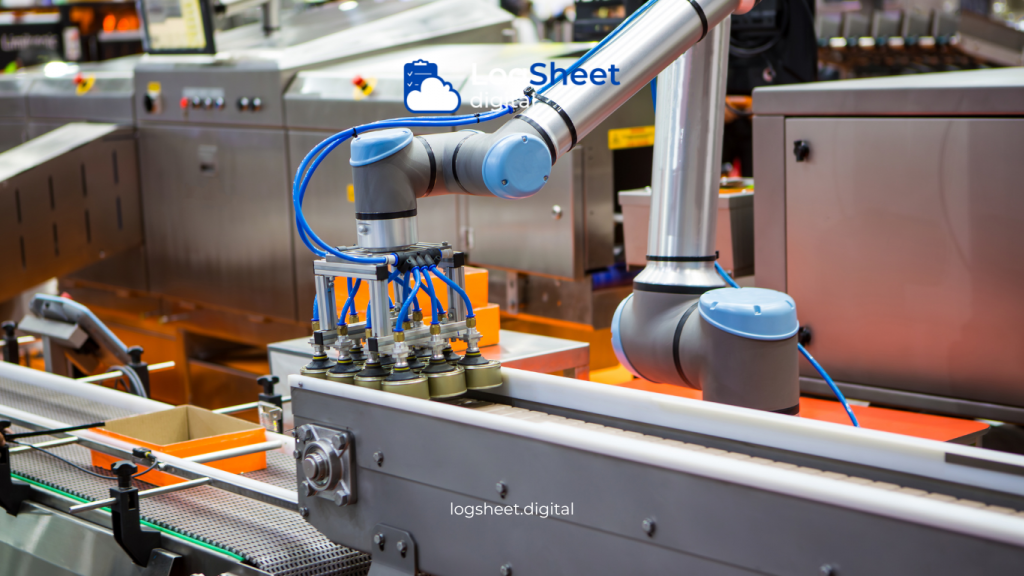

1. Manufacturing Industry

In the manufacturing industry, digital logsheets play a vital role in machine management and production monitoring. With digital logsheets, companies can monitor machine performance in real-time and reduce the risk of machine damage or failure. Additionally, these logsheets allow companies to anticipate preventive maintenance needs, minimizing downtime.

2. Energy Industry

In the energy industry, digital logsheets are used to monitor energy production and distribution. With data obtained from digital logsheets, companies can optimize energy usage and identify inefficiencies. This is crucial in efforts to reduce carbon footprints and improve operational sustainability.

3. Logistics Industry

In the logistics industry, digital logsheets help companies track the movement of goods and ensure that the distribution process runs as planned. With digital logsheets, companies can track shipment statuses in real-time, minimizing the risk of delays and ensuring customer satisfaction.

Challenges in Implementing Digital Logsheets

Read More: Receiving Raw Materials: Current Production Health

1. Implementation Costs

One major challenge in implementing digital logsheets is the initial investment cost. Companies need to invest in the necessary hardware and software to support digital logsheets. However, this investment often pays off in the long run with improved efficiency and reduced operational costs.

2. Employee Adaptation

Another challenge is the adaptation of employees to new technology. Some employees may struggle with transitioning from manual methods to digital logsheets. Therefore, adequate training and education are crucial to ensure that the entire team can effectively use this technology.

3. Integration with Existing Systems

Companies may also face challenges in integrating digital logsheets with existing systems. Some companies may have production systems that have been in place for years, and transitioning to digital technology can be a complex process.

The Future of Digital Logsheets

Read More: Digital Logsheets Effectively Reduce Production Disruptions

In the future, the use of digital logsheets will expand as Industry 4.0 technology evolves. Integration with technologies such as the Internet of Things (IoT) and artificial intelligence (AI) will provide deeper analysis capabilities and higher levels of automation. Companies that adopt these technologies will gain a competitive edge in the global market.

Conclusion

Read More:

Digital logsheets are a crucial tool in developing production processes and enhancing industry competitiveness. With the ability to collect real-time data, reduce human errors, and provide in-depth analysis, digital logsheets help companies achieve better operational efficiency. Additionally, these logsheets support compliance with industry standards and enable companies to respond to market changes more rapidly. Despite some challenges in implementation, the long-term benefits of digital logsheets make them a valuable investment for companies across various industry sectors. By continuing to advance this technology, companies can strengthen their competitiveness in the modern industrial era.

leave your comments